Facilities

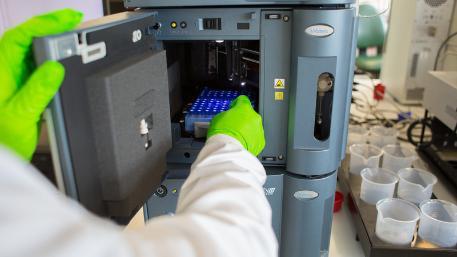

Excellent research facilities and equipment

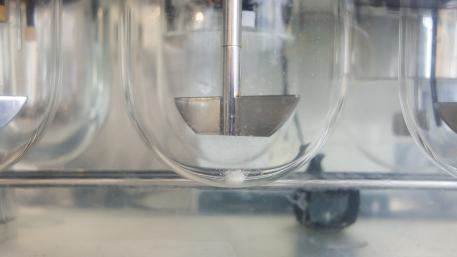

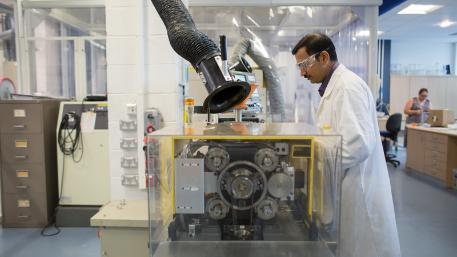

The Centre for Pharmaceutical Engineering Science is located across the University’s city campus having laboratories in the Norcroft Building and the Polymer IRC the centre provides a wide range of excellent research facilities and equipment. Our clean room melt extrusion and injection moulding processing facilities are housed in the Polymer IRC building.