Areas of Expertise

Product and process understanding

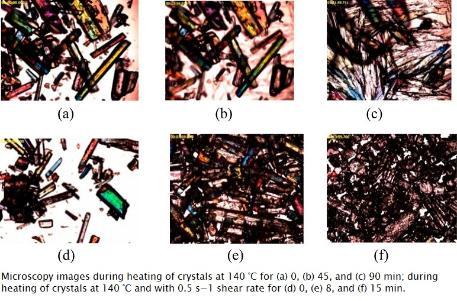

The academic research team led by Prof Anant Paradkar at CPES is focused on developing an in-depth fundamental understanding of the influencing factors on both product and process development in the pharmaceutical and related industries. Our research themes cover crystal engineering, cocrystals, amorphous forms, polymorph stabilisation and innovative drug delivery technology. The team are experts in solving pharmaceutical and nutraceutical product and manufacturing problems and use a QbD approach to systematically understand the key aspects of process and product development.

-457x304.jpg)

-411x394.jpg)