Facilities

The Centre for Visual Computing has access to the latest equipment in all the fields in which we operate.

This includes 3D non-contact scanning facilities, an industry standard motion capture suite and a video eye tracker.

Video eye tracker

The Video Eye Tracker allows you to easily add eye tracking to investigations where the display is a computer monitor.

The eye tracker is mounted on a rigid headrest that incorporates the camera, illumination and optics. It can be used with almost any Windows programming environment to measure gaze direction, eye rotation or fixation monitoring. Data is available in the following real-time forms:

- X-Y eye position at a specified frequency

- X-Y velocity

Overall, the system is exceptionally easy to use with minimal configuration requirements. Its sophisticated image processing algorithm is intelligent, adaptive and extremely robust regarding lighting conditions and variations in individual subjects. No operator adjustments of thresholds are required.

Special effects studio

Our special effects studio consists of a retro-reflective dual colour (blue / green) chroma key suite with retro-reflective chroma flooring.

It allows full body capture direct to PC 4:2:2 digital video capture in full 1080p HD or SD using Sony XDCAM EX cameras.

These capabilities are supported by the following:

- 2 TB Raid storage

- Dell 2.0 GHz Xeon Quad Core Workstation

- HD Video Assist with chroma key live view function

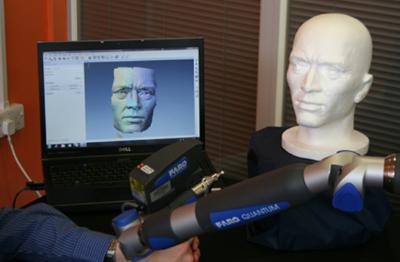

3D laser scanning

Our non-contact 3D digitising facility can instantaneously digitise the external profiles of various industrial parts – including press parts, machined parts, dies, prototypes, cast parts and injection moulded parts – into 3D data.

The digitised profile data can then be accurately reproduced on a computer screen. By comparing this data against 3D CAD data with optional application software, we can quickly output measurement reports on overall deviation, cross-sectional deviation, wall thickness distribution and GD&T (Geometric Dimensioning and Tolerance).

As well as measurement for inspection and quality control, our facility offers various applications including:

- Reverse engineering

- Rapid prototyping

- Creation of machining data

- Digital mockup

Laser Scanners

The Centre for Visual Computing has two pieces of laser scanning equipment for different applications: a FARO Arm Laser Scanner suitable for engineering components and artefacts, and a FARO Laser Scanner P120 which rotates 360° and measures everything within its line of sight up to 120m away.

FARO Laser ScanArm V3

The FARO Laser ScanArm V3 enables the inspection of parts in detail by capturing huge point-cloud data. It tackles all measurement tasks like inspection, point cloud-to-CAD comparison, rapid prototyping, reverse engineering, and 3D modelling. Its main benefits are the exact scanning of reflective and dark objects, the biggest challenge for all scanning systems.

FARO Photon 120 Laser Scanner

The P120 is a large-scale high speed 3D scanner for full detail survey work. Using non-contact laser technology, it rapidly generates detailed three dimensional replicas of complex environments and geometries. The resulting image is a collection of 3D measurements, providing an accurate digital representation of as-built or as-is conditions.

Motion capture

The Centre has access to an industry standard motion capture studio equipped with 16 Vicon T20 cameras.

The T20 captures 500 frames per second at 2 megapixels resolution, allowing it to accurately capture high speed movements. It is a system capable of capturing both full body and detailed facial movement.

The motion capture unit has been used to produce 3D animation for several major game publishers including SEGA, Codemasters and Atari, and to produce a series of broadcast television idents for the UEFA Women's Euro 2009.

Thermal camera equipment

Our thermal imaging facility uses state-of-the-art infrared imaging technology that detects infrared radiation/ heat. From the detected temperature differences, thermal imaging cameras can create a crisp image. By using complicated algorithms it is possible to read correct temperature values from the image.

Thermal Image Cameras can be used for many things, for example:

- Solar Panels inspection

- Thermal surveillance of volcanos

- Vein cartography

- High transient analysis

Thermal Camera Specification

- At the Centre of Visual Computing we use the FLIR ThermoVision™ A-Series Infrared Camera A320

- Image Size: 320 x 240 pixels

- Image Frequency: 9 Hz

- Temperature Range: -20 °C to + 350 °C (+ 1200 °C optionally)