Award winning project for greener stretch wrapping

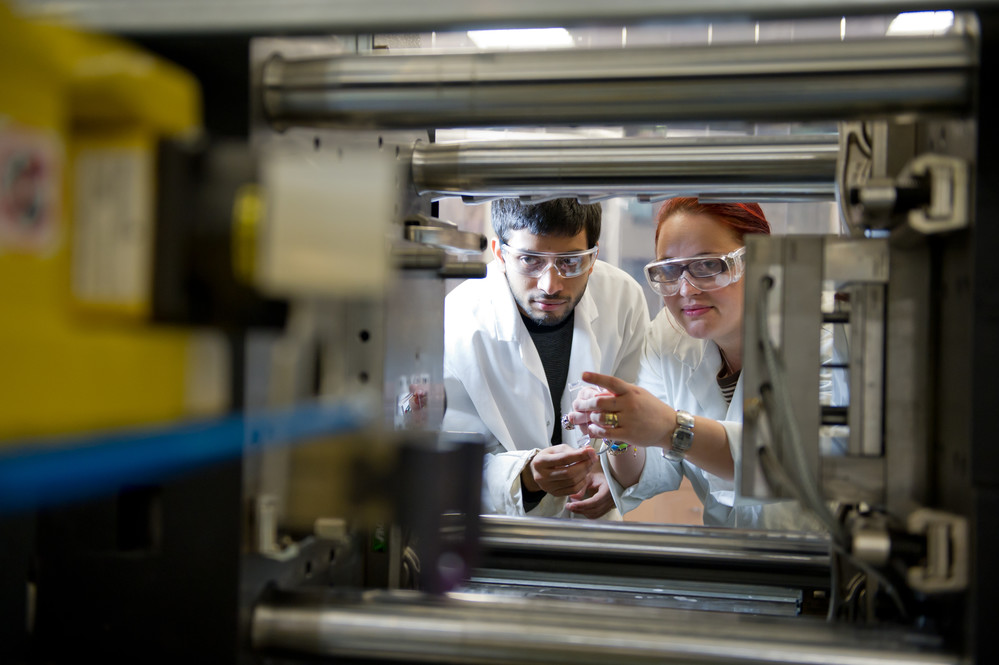

Our Centre for Polymer Micro and Nano Technology has been fundamental in helping DHL adopt a greener shrink-wrapping for packaging aerosols.

Working alongside TrakRap Ltd, the Manufacturing Technology Centre, and DHL; Professor John Sweeney and Dr Cristina Tuinea-Bobe from the Faculty of Engineering and Informatics helped identify a novel stretch wrapping process that is greener and safer than shrink wrapping.

TrakRap develop sustainable packaging solutions and asked the University of Bradford to help them identify an alternative plastic wrapping for their application. Cristina and John, specialists in polymers, concentrated on materials analysis, selection, and development.

Their work involved studying 9 materials, testing them in the polymer lab, and recommending the best performing one for this application. The stretch wrapping chosen by TrakRap involves no heating of the wrapping material and saves considerable energy. It is also safer to use. The improved stretch wrapping is now in use by DHL, who particularly needed something that didn’t involve heating for wrapping aerosols prone to explosion under heat pressure.

Through this valuable project, the university gained a better understanding of the packaging sector, and the team of scientists got the opportunity to carry out high impact research related to a UK market valued at £430m (Source: MongoDB Inc).

The project has been such a success, that it won the 2019 Innovation Award from the Food and Drink Federation and the Innovative Packaging Machinery Award at the PPMA 2019 show.

Visit the Centre for Polymer Micro and Nano Technology.